TRADITIONS

When we build a Pallet, we do it as if for ourselves, it makes you happy

Hunting Line

011 - 3323 8836

About Bina Jaya Global

Bina Jaya Global Sdn Bhd is a successful company which supplies high quality wood products to meet a wide range of specifications. Established in 2011, Bina Jaya Global Sdn Bhd is based in Pulau Pinang, Malaysia. Among these few years, Bina Jaya Global Sdn Bhd has positioned itself over the years as one of the reliable manufacturers of wooden pallets, wooden crates, wooden cable drum and wooden boxes. Pallet, crates, cable drum and boxes that manufactured by Bina Jaya Global Sdn Bhd are custom made to meet all of our customer specific requirement and size.

Bina Jaya Global Sdn Bhd itself have sawmill facilities that enables us to cut rough saw timber into various sizes which later will be manufactured in to wooden pallets, wooden crates, wooden cable drum and wooden boxes. Our timber is mainly supplied by a local supplier and hence allows us to maintain an inventory of raw materials at hand in order to meet demands.

ISPM15 – INTERNATIONAL PHYTOSANITARY STANDARD FOR WOOD PACKAGING

Bina Jaya Global Snd Bhd complies with the ISPM 15 standard – “International Standard Phytosanitary Measures for Wood Packaging” by providing Heat Treatment Services for the export of wooden pallets and wood packaging materials.

In order to comply with the export regulations on “Wood Packaging Materials”, MTW also offers Heat Treatment Services according to the ISPM 15 standrads, i.e IPPC – International Plant Protection Convention, on wooden pallets and wood packaging materials as set forth in the guidelines issued by the Department Agriculture in Malaysia.

OUR MISSION AND VISION

A DRIVING FORCE THAT KEEPS US GOING

We are comitted to be a professional and dependable company, willing to take on new challenges so as to maximize your profits.

We recognize the importance of our services, and will utilize technology to our advantage to deliver quality solutions and ensure that our clients’ goods are always shipped out safely and timely to their destination points without any hassle.

OUR CLIENTS

WE SERVE IN DIVERSIFIED DOMAINS

Many MNCs, Conglomerates and International Brand Owners. The following are some of the industries

that we serve in:

- Freight Forwarding

- Information Technology

- Telecommunications

- Electronics

- Aerospace

- Sensitive Technology

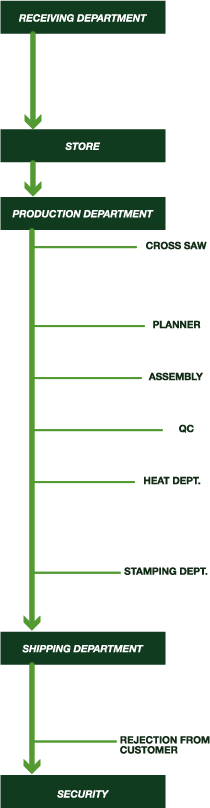

Work Flow Chart

- Visual checking on item with D/O.

- Check Quantity and quality.

- Mark on item for FIFO.

- Found defect mark on item and D/O. Take photo.

- Acknowledge the supplier through telephone and e-mail.

- Issue Debit Note.

- Brought on charged and forward to store.

- Received, record and store at proper area.

- Upon received Job Sheet.

- Issue out the material to production as per request.

- Collect the material with Job Sheet Request.

- Supervisor to advise the operator to cut the material accordingly.

- Operator to cut and reap material to size.

- Upon completion operator to inform supervisor.

- Planed the sizes plank to free from dust and splinter.

- Supervisor to inform upon completion.

- Operator to prepare the mould.

- Runner, block and plank to place on the mould.

- Nail accordingly using the nail gun.

- Random check for size and dimension.

- Ensure finished product with quality product such as free from hole, fungus and decay.

- Pallet to load into the heating chamber.

- Chamber operator to control the heat through the control recorder.

- Switch off the chamber upon reaching the measurement through recorder.

- Off load the pallet and placed at treated area.

- Stamp at the pallet as per customer request such as part number, IPPC chop and company name by using rubber wood stamp.

- Placed/arranged the pallet.

- Receive D/O and Invoice.

- Arrange transport.

- Load into lorry as per D/O quantity.

- Driver to ensure for correct quantity.

- Ensure cover the pallet with canvas before transporting.

- Admin to inform production.

- Arrange transport for collection and replacement.

- Guard to check and ensure for the incoming and outgoing item through D/O and Invoice.